Advances in construction technologies are rapidly transforming the architecture and construction industry. Traditionally perceived as labor-intensive and repetitive, the construction industry is gradually moving towards a more manufacturing-based approach. This shift has profound implications for the design process, labor force, and overall project execution.

This article delves into the significant changes in construction technology and their impact on architecture and design.

The Evolution of Construction Practices

The construction industry has long relied on site-specific, labor-intensive methods. Each new project requires setting up site offices, sample flats, and infrastructure works from scratch. However, the industry is on the cusp of a transformation, moving towards manufacturing-supported and assembly-based solutions. This transition promises to streamline construction processes, enhance efficiency, and potentially reduce costs.

Key Technological Innovations

1. Prefabricated Construction

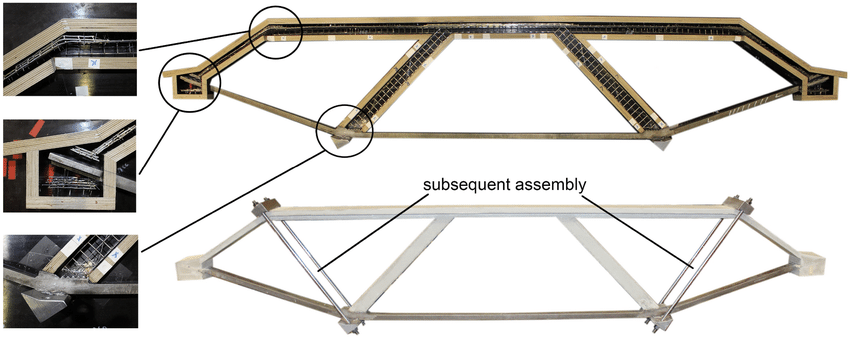

Prefabrication involves manufacturing building components in a factory and assembling them on-site. This can range from element-wise prefabrication, such as bathroom pods installed in a cast-in-situ structure, to complete building assemblies manufactured off-site. This method offers significant time and cost savings while improving quality control.

- Element-wise Prefabrication: Individual components such as walls, floors, and roofs are prefabricated and transported to the site. This approach allows for greater flexibility in design and is particularly useful for large-scale projects.

- Composite Prefabrication: Combines various prefabricated elements into larger assemblies, such as entire rooms or sections of buildings. This reduces on-site construction time and minimizes disruptions.

- Complete Prefabrication: The entire building is manufactured off-site and then assembled on location. This method ensures high precision and quality while significantly reducing construction time.

2. 3D Printing

While still in its early stages, 3D printing has made remarkable strides. Small standalone residential developments have been successfully completed using this technology. Although not yet widely adopted for commercial or high-rise developments, 3D printing is in a promising ‘beta’ stage for future applications.

- Residential Applications: 3D printing has been used to construct small houses with complex designs that would be difficult to achieve using traditional methods.

- Material Efficiency: 3D printing minimizes waste by using only the necessary amount of material, making it an eco-friendly option.

- Customization: Offers unparalleled design flexibility, allowing for the creation of bespoke structures tailored to specific needs.

Explore more about 3D Home Design – Planning and Visualization

3. Drones

Drones are revolutionizing construction supervision by capturing live data from project sites. They provide aerial views, high-resolution images, and real-time updates, helping to identify potential issues and monitor progress efficiently.

- Surveying and Mapping: Drones can quickly survey large areas, creating accurate topographical maps and models.

- Safety Inspections: Drones can access hard-to-reach areas, conducting safety inspections without putting workers at risk.

- Progress Monitoring: Regular drone flights can document the progress of a construction project, providing stakeholders with up-to-date information.

4. Robotics and AI

Construction equipment manufacturers are developing robotic machinery for common tasks such as concrete pouring and vibrating. AI is also being integrated to optimize various construction processes, enhancing productivity and safety.

- Robotic Construction: Robots can perform repetitive and hazardous tasks, such as bricklaying, with high precision and efficiency.

- AI Integration: AI algorithms can analyze data from construction sites to predict potential issues and optimize workflows.

- Autonomous Machinery: Self-driving construction vehicles can transport materials around the site, reducing the need for manual labor.

New Formwork Technologies

Formwork is the temporary or permanent molds into which concrete is poured. Innovations in formwork technology are significantly improving construction efficiency, reducing costs, and enhancing safety. The following are some of the latest advancements in formwork technology:

Plastic Formwork

Plastic formwork systems are lightweight, modular, and reusable. They are made from high-strength, durable plastic components that can be easily assembled and disassembled. The advantages of plastic formwork include:

- Ease of Handling: The lightweight nature makes it easy to transport and handle, reducing labor costs and effort.

- Durability: Resistant to rot, corrosion, and chemicals, ensuring a long lifespan and low maintenance requirements.

- Cost-Effective: Reusability reduces overall formwork costs over multiple projects, making it a cost-efficient option.

- Sustainability: Being reusable makes it an eco-friendly option, contributing to sustainable construction practices.

Aluminum Formwork

Aluminum formwork is known for its strength, durability, and reusability. It consists of panels made from high-grade aluminum alloy, which are lightweight yet strong. Key benefits of aluminum formwork include:

- High Strength-to-Weight Ratio: Provides robustness without adding excessive weight, making it easier to handle and transport.

- Speed of Construction: Easy to assemble and disassemble, allowing for faster project completion and reduced labor costs.

- Precision: Ensures accurate dimensions and smooth finishes, improving the overall quality of the construction.

- Reusability: Can be reused numerous times with minimal maintenance, making it a cost-effective solution for large-scale projects.

Hybrid Formwork Systems

Hybrid formwork combines different materials like steel, aluminum, and plastic to leverage the advantages of each. These systems are designed to optimize performance, reduce costs, and enhance flexibility. Characteristics of hybrid formwork include:

- Versatility: Can be adapted to various project requirements, offering flexibility in design and construction.

- Efficiency: Combines the best properties of multiple materials, ensuring high performance and durability.

- Cost Savings: Optimizes material usage, reducing overall costs while maintaining high quality.

Impact on Architectural Design

The integration of these technologies necessitates a shift in the architectural design process. Designs must now align with manufacturing-based setups, particularly for large-scale residential projects. Key considerations include:

- Grid Frameworks: Adopting standardized grid frameworks influences the selection of formwork technologies, ensuring compatibility and ease of assembly.

- Standardized Elements: Using standardized doors, windows, and other elements facilitates easier installation and repetition, improving efficiency and reducing costs.

- Engineered Materials: Utilizing artificially engineered marble, stone, and innovative façade panels simplifies construction and enhances durability, offering a wide range of design options.

Future Prospects in Construction Technology

The future of construction technology is poised to bring even more innovations. Building Information Modeling (BIM) systems and precast construction techniques will allow for complete designs conceived by consumers and delivered directly to their sites. Augmented Reality (AR) and Virtual Reality (VR) will enable clients to visualize designs in real-time, while advanced estimation tools will provide accurate cost projections.

Learn more about BIM Execution Plan: A Comprehensive Overview

Tools for Modern Construction Projects

- Building Information Modeling (BIM): Essential for integrated project planning and management, enabling collaboration among stakeholders and improving project outcomes.

- Augmented Reality (AR) / Virtual Reality (VR): Enhances design visualization for clients and stakeholders, providing immersive experiences and improving decision-making. Learn more about Augmented Reality and Virtual Reality in Real Estate and AEC Industry

- Automated Estimation Tools: Facilitate real-time cost and material estimations, ensuring accurate budgeting and reducing the risk of cost overruns.

- Parametric Modeling Techniques: Tools like Dynamo and Grasshopper for Rhino 3D enable sophisticated feasibility studies and design optimization, allowing for innovative and efficient designs.

The shift in construction technology is revolutionizing the industry, impacting design processes, and offering new tools and techniques for architects, developers, and end-users. Embracing these advancements is crucial to staying ahead in the ever-evolving construction landscape. From prefabrication to 3D printing, drones, robotics, and new formwork technologies, the future of construction promises to be more efficient, cost-effective, and innovative.

What do you think about these tools and their relevance for the future of the construction industry? Share your thoughts in the comments below!